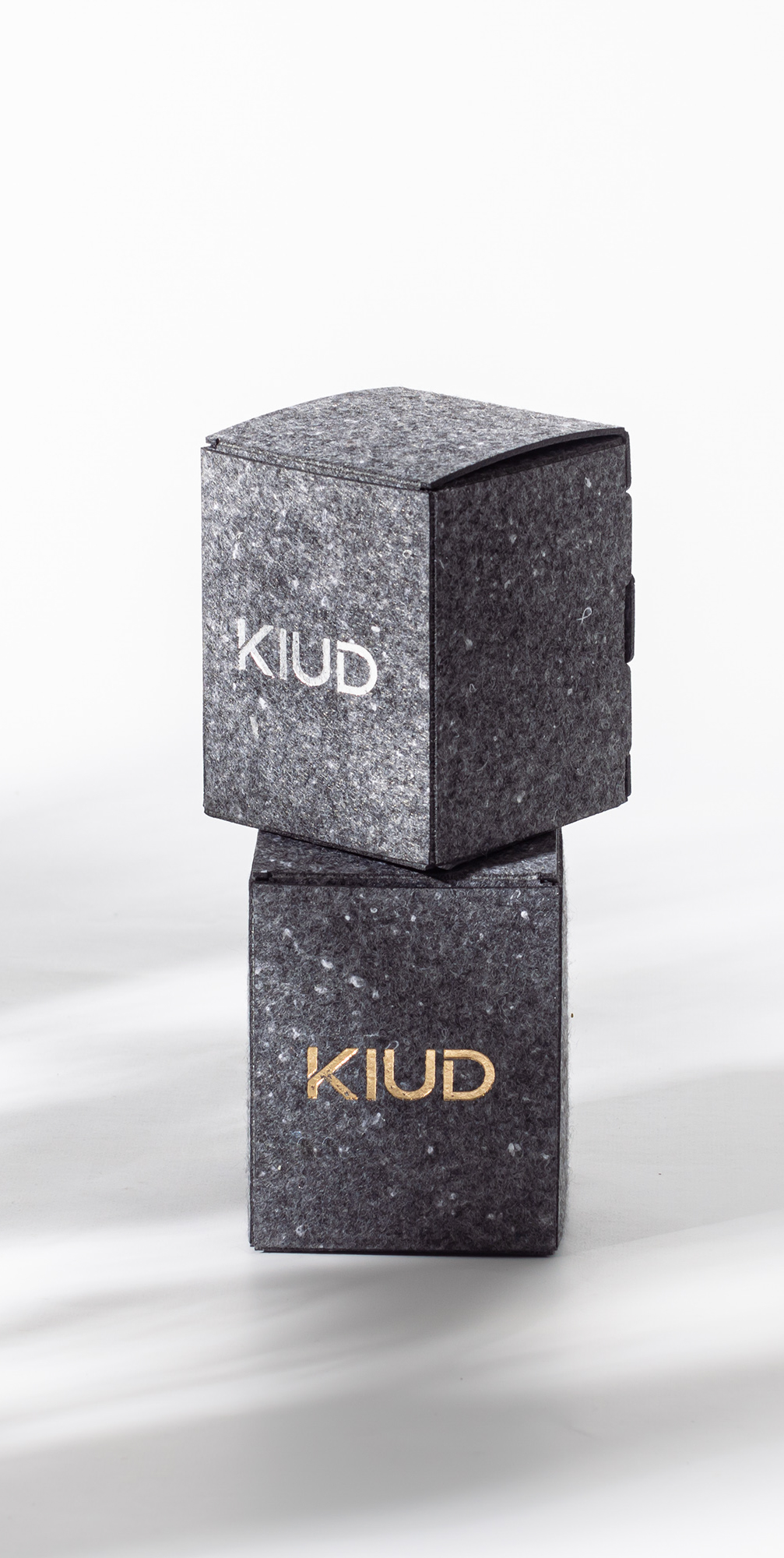

Packaging that complies with the Green Deal

KIUD offers solution that not only aligns with the EU Green Deal but also embodies the principles of the circular economy within the fashion and textile sector.

78% of textile waste generated in EU is today landfilled, incinerated or exported to Africa.

We repurpose this valuable circular material into the most widely used products – a high quality and durable premium packaging.

ESG compliance

Packaging from recycled textile waste complies with the ESG requirements.

Reducing CO2

Contribution to circular economy and reduction of the carbon footprint.

Market differentiation

Novel packaging enables to differentiate brands in the market.

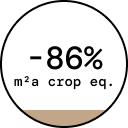

The environmental impact of KIUD

Life cycle impact assesment for comparing both textile waste and cardboard packaging systems was carried out using the 2016 ReCipe (H) midpoint method across 18 impact categories, using OpenLCA platform.

Carbon footprint

This category assesses and focuses on the emissions of the greenhouse gases, such as carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O), which contribute to Earth’s rising temperatures and the climate change.

Water use

This category assesses the amount of water withdrawn or consumed throughout the life cycle of the product or the activity. It takes into account both the direct use of water and the indirect water footprint associated with processes or inputs.

Land use

This category assesses the environmental impact associated with the change of land use. Land use refers to the occupation, transformation, or alteration of the land for various purposes – agriculture, urban development, or industrial activities.

Prerequisites of our research

The rigid packaging made of textile waste has numerous advantages over the cardboard.

It comes with a positive environment impact and helps up valueing mixed textile waste that is difficult to recycle.

Cardboard packaging

Production

Cardboard boxes have long been the standard packaging material for parcel deliveries. However, their widespread use comes with significant environmental consequences. The production of cardboard boxes requires the felling of trees, contributing to deforestation and habitat loss.

Additionally, the manufacturing process involves large amounts of water, energy, and chemicals, leading to greenhouse gas emissions and pollution. Moreover, the disposal of cardboard boxes often results in them being sent to landfills, where they decompose and emit methane, a potent greenhouse gas.

Sustainability

Cardboard boxes are generally believed to be fairly sustainable for their expected high content of recycled cardboard and other timber wastes and by-products.

However, while in the developed world 90% of cardboard thrown away is collected for reuse and recycling purposes, only 54% of thrown away cardboard ends up in the actual new cardboard production.

The rest is made into various other products, incinerated, or landfilled.

Textile waste packaging

Production

In contrast to cardboard boxes, the packaging made from recycled textile waste offers a compelling alternative with numerous environmental advantages.

By utilizing discarded textiles, such as old clothes and fabrics, as the raw material for packaging, this approach reduces the need for new resource extraction and landfill space.

Additionally, using recycled textiles in packaging could reduce water consumption, as it eliminates the need for extensive processing and bleaching required in cardboard manufacturing.

Sustainability

By embracing the packaging made of recycled textile waste, brands can contribute to the circular economy, divert the waste from landfills, and reduce their own carbon footprint. KIUD packaging enables to align with the ESG requirements, differentiate brands in the market and contribute positively to the environment.

Such packaging also resonates with consumers who are increasingly seeking for sustainable products and are likely to appreciate businesses that prioritize environmental responsibility.

KIUD packaging is recyclable back to textile fibers

KIUD material consists of 100% of textile waste fibers and is thermomechanically processed without using any chemicals or water. This enables to recycle KIUD packaging back to fibers at the end of their lifecycle.

We work with our customers on developing cost-effective and efficient schemes for collecting back discarded KIUD packaging.